Objectives:

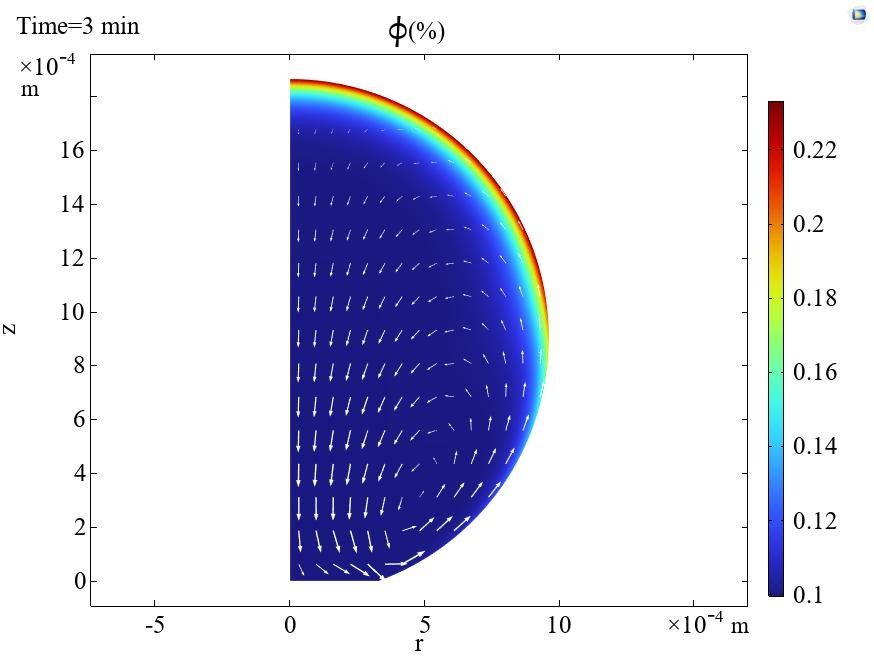

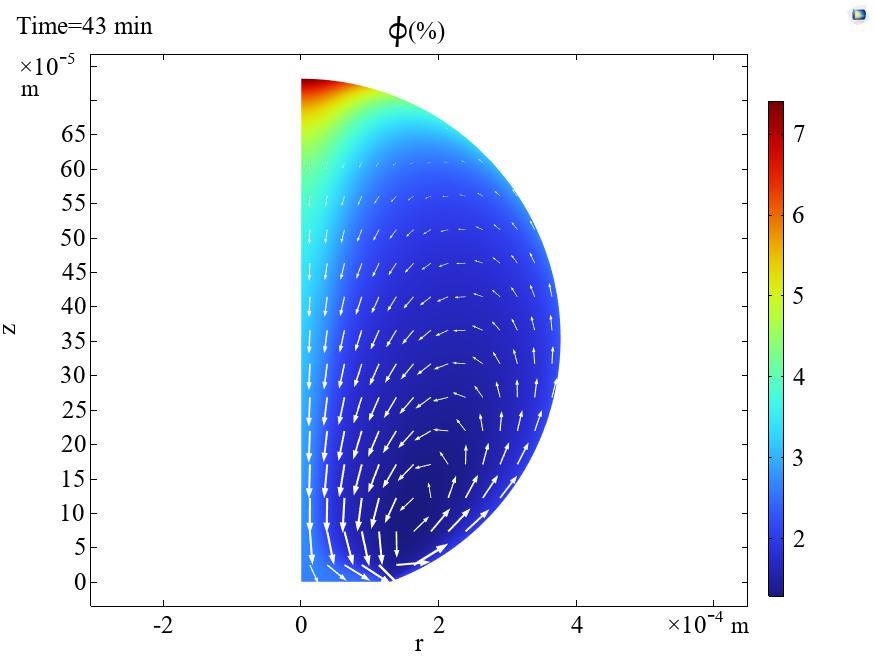

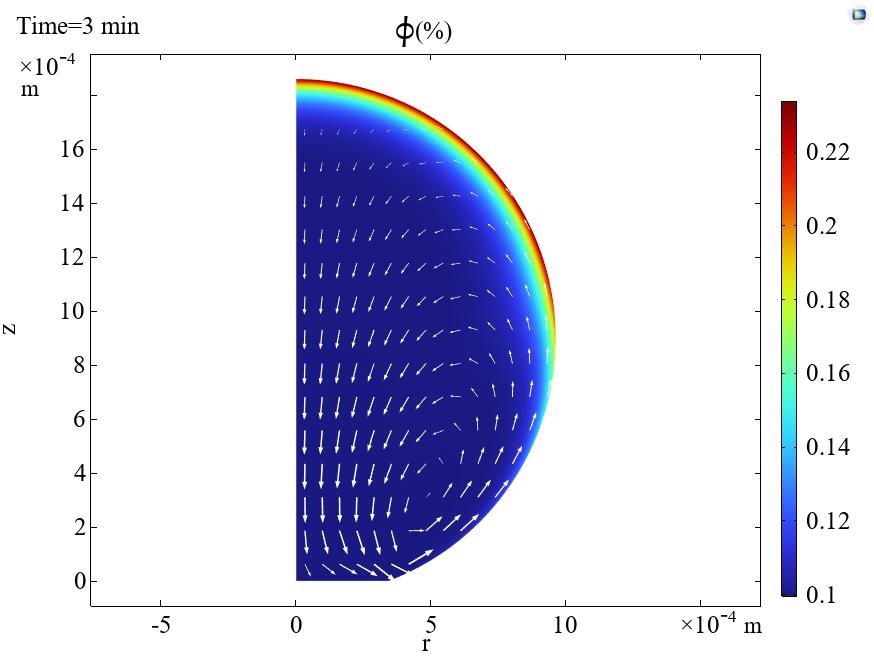

To develop and validate a theoretical/numerical model describing formation of nanoparticle assemblies and to apply this model to formation of supraparticles and to formation of conductive printed circuits

Expected Results:

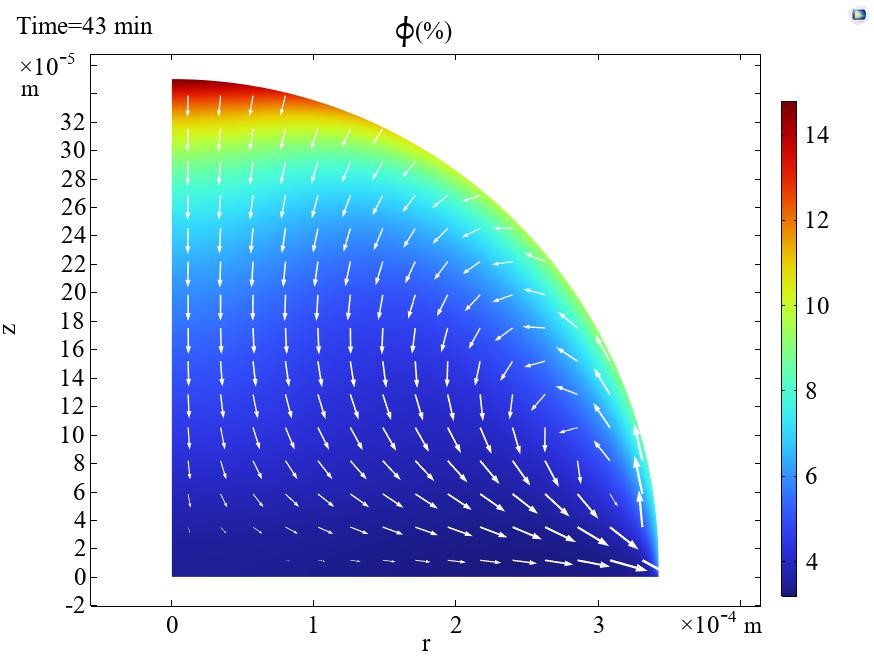

– Theoretical model and computer code describing flow and assembly of nanoparticles on substrates on the basis of colloidal nanoparticle interaction and nanoparticles dynamics model (WP1), interfacial flows model (WP2) and taking into account solvent evaporation;

– simulation of self-assembly of particles during coalescence and evaporation of two nanosuspension drops on a superoleophobic substrate (MPIP);

– simulation of formation of assemblies by evaporation of printed conductive inks/pastes (ICSC).