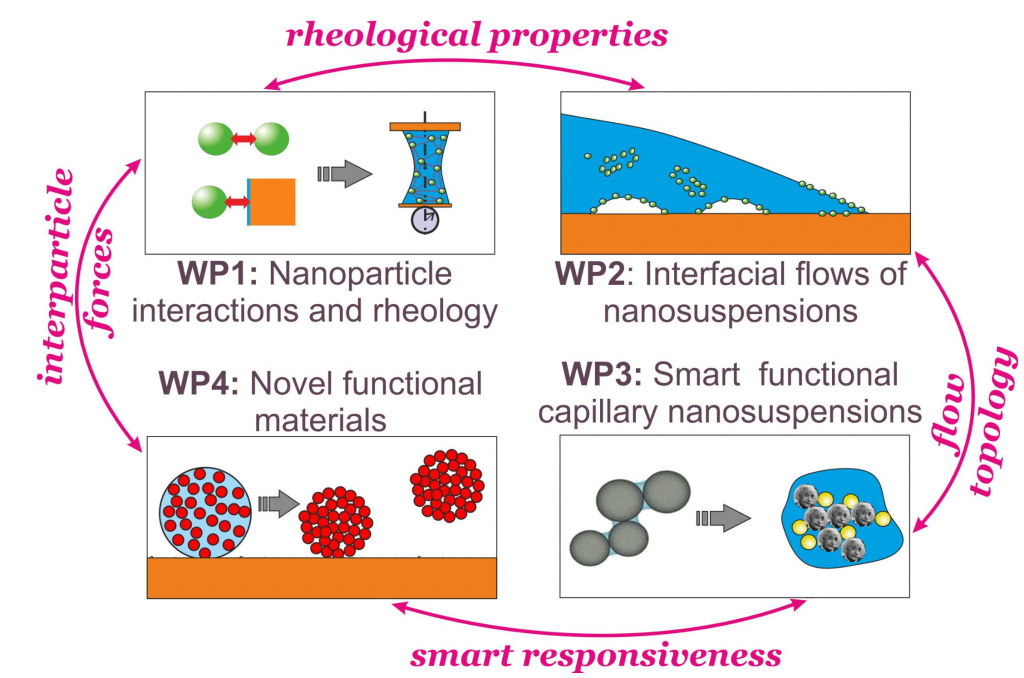

The main research objectives of nanoPaInt include

- development and experimental validation of a predictive model for nanoparticle dynamics and rheology of dense nanosuspensions. This dynamics is governed by strong colloidal and capillary nanoparticles interactions in bulk and at interfaces.

- development and experimental validation of a model describing nanosuspensions dynamics in complex interfacial flows, including flows with change of topology and wetting/dewetting flows in the presence of surfactants

- design and development of smart, stimuli-responsive capillary nanosuspensions

- development and optimization of new pathways for design of functional nanomaterials and parts

Work package 1: Nanoparticle interactions and rheology of nanosuspensions

In WP1 the interactions between the nanoparticles in liquid bulk and at fluid interfaces will be related to nanoparticles dynamics and to the bulk and surface rheology of nanosuspensions. The dynamics of nanoparticles will be simulated by solving the Langevin equation for the systems, in which the range of colloidal interactions significantly exceeds the particle size.

The simulations will lead to development of a breakthrough theory for the nanoparticles clustering, and further to development of model describing rheology of nanosuspensions and nanoemulsions.

Work package 2: Interfacial flows of nanosuspensions

This work package is focussed on investigation of dynamic interfacial flows which are

important for manufacturing and application of functional nanomaterials. This includes the fast elongational flow in liquid bridge, flow of films and sessile drops induced by vibrations and fast spreading under influence of surfactants. In these flows the relation between the time scale of the flow and the time scale of nanoparticles dynamics, including the adsorption/desorption kinetics, plays an important role.

Work package 3: Smart functional capillary nanosuspensions

In this work package, capillary nanosuspensions will be designed and fabricated with the forces between the nanoparticles responding to external stimuli or chemical reactions, which allows programming the response of the suspensions to changes in environmental pH, temperature or salinity. Capillary suspensions can also be used as precursors for fabrication of porous ceramic materials. The combination of microparticles and nanoparticles leads to a significant increase in the compressive strength of the resulting material. The combination of nanoparticles with different wettabilities enables the fabrication of smart porous materials that can be applied, for example, for the separation of liquids.

Work package 4: Novel functional nanomaterials

This WP is devoted to development and optimization of routes for manufacturing of novel functional nanomaterials from dense nanosuspensions on the basis of knowledge gained in the previous WPs. We shall demonstrate the applicability of nano-suspensions with controlled properties for manufacturing of functional materials and parts at different scales and shapes: micron-sized supraparticles, printed electronic circuits, porous materials and objects manufactured using 3D-printing process. Their applications include catalysis, gas adsorption, filtration, liquids separation and drug delivery.